| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Sussman

Model Number : SM-BD

Certification : CE

Place of Origin : Wuxi Jiangsu China

MOQ : 1 set

Price : negotiable

Payment Terms : T/T L/C, D/P, Western Union, MoneyGram

Supply Ability : 10 sets per months

Delivery Time : 60 days after deposit

Packaging Details : Standard packing

Material Thickness : 0.7-1.2mm

Forming Speed : 12-15 m/min

Main Motor Power : 7.5Kw * 2

Forming Stations : 27 stations

Material : galvanized coils

Cutting : hydraulic cutting; quenching HRC58-62

Drive system : chain drive

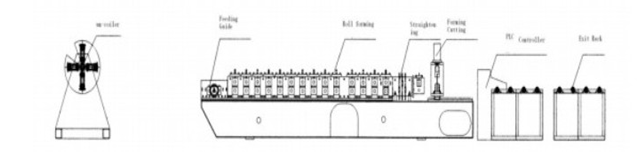

184mm Width 0.7mm-1.2mm Thickness Metal Shutter Door Bottom Roll Forming Machine With Fly Saw Cutting

Advantages of the Machine

1.The design of the Security Door Frame Making Roll Forming Machine is convenient to adjust, for it owns reasonable structure, compact shape, high precision and high efficiency.

2.The manufacturing process of the complete machine is in strict accordance with the mechanical standards, tracking and controlling the manufacture of each part.

3.Professional team for technical research and development, providing users with automatic plate processing equipment of high quality and efficiency.

4.The entire line is controlled with PLC, with touch screen of display and operation and high automation.

Shutter Door Bottom Technical Parameter

1. Steel Sheet Thickness: 0.7-1.2mm (depend on requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching, circular pitch: 38.1, number of teeth:13

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 3 ton passive decoiler

6. Forming Speed: 12-15m/min

7. Roller Groups: 27 stations upper and 16 stations down

8. Roller Material: Cr40 steel precision-machined, high frequency quenching treatment, HRC58-62

9. Material: galvanized steel

10. Principal Axis: 45# high grade steel with quenching treatment

11. Main Motor Power: 7.5 Kw * 2

12. Water cooling system

Shutter Door Bottom Main Components

| S.N | Equipment name | Quantity |

| 1. | 3T passive un-coiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 5. | Main roll forming machine 27 stations drived by chain | 1 set |

| 6. | Fly saw cutting | 1 set |

| 7. | Control system (including control box) | 1 set |

| 8. | Out tables | 2 sets |

| 9. | Water cooling system | 1 set |

Working Flow of Shutter Door Bottom

Decoiler----Feeding and Leveling---Roll forming---Fly saw cutting---Run out tables

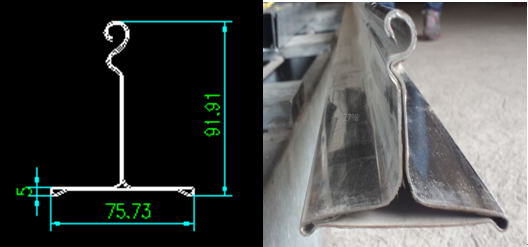

Profiles of Shutter Door

Machine Photo

|

|

184mm Width 0.7mm-1.2mm Thickness Metal Shutter Door Bottom Roll Forming Machine With Fly Saw Cutting Images |