| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Sussman

Model Number : SS-BB

Certification : SGS,CE.ISO

Place of Origin : China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 10 sets per month

Delivery Time : 70 days

Packaging Details : standard packing

Name : Box Beam Roll Forming Machines

Material : Galvanized Steel Plate

material thickness : 1.0mm-2.5mm

Forming stations : 15 stations

Roller material : GCR12 bearing steel

Dirve system : Chain drive

power supply : 440V, 60Hz, 3Phase or customized

Forming speed : 8-10m/min

Machine weight : about 8 tons

Machine Size : 12mx1.4mx1.6m

Servo Feeding Device Upright Frame Cold Roll Forming Machine 11 kw

Main Roll forming machine technique data

Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel

Working Speed: 12-15 meters / min

Forming Steps: 18 stations

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

Driven system: Chain Driven 1.5 inches 20A double chain with longer shafts

Main Power with reducer: 11KW WH Chinese Famous

Cutting: Hydraulic Cutting Cr12mov

Material of Cutting Knife: Cr12Mov, Quench HRC58-62

Hydraulic Station Power: 7.5KW Wuxi Wanshen Famous Chinese Brand

The whole machine is controlled by industry computer-PLC.

PLC--Panasonic, Japan English and Chinese Language

Touch Screen--Panasonic Japan

Encoder--Omron, Japan

Electric parts--Schneider

Cutting holder: straight cutting by 3 pieces of blades

Main Components

| No. | Item Name | Quantity | Remark |

| 1 | Manual de-coiler | 1 set | 3 tons |

| 2 | Leveling machine | 1set | Wannan motor |

| 3 | Cutting device | 1 set | Engineer define |

| 4 | Punching device | 2 sets | Hydraulic Prepunching |

| 5 | Roll Forming Machine | 1 set | ¢75mm |

| 6 | Cutter mold | 6 units | Engineer define |

| 7 | Hydraulic station | 1 set | Engineer define |

| 7 | Product stand table | 5 sets | 2 m*5 |

| 8 | Folded machine | 1 set | ¢75mm *4 |

| 9 | Tool Box | 1 box | standard |

| 10 | Books | 1 book | Use manual, Wire diagram, Machine layout drawing, Maintenance book, |

| 11 | Spare parts | 1 set |

|

Roll Formed Pallet Rack Advantages:

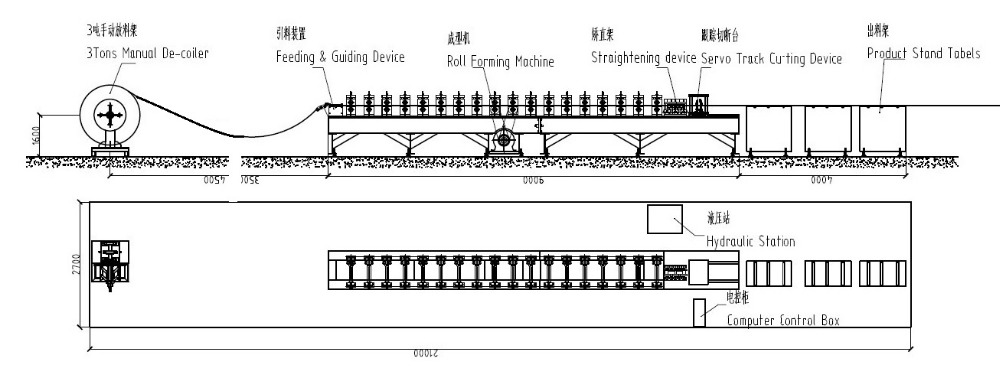

Working Flow of Roll Forming Machine

Manual de-coiler-->leveling machine -- roll forming machine –Cutting device–>Product Stand Tables

Photo Gallery

Production process

Why choose us

|

|

Servo Feeding Device Upright Frame Cold Roll Forming Machine 11 kw Images |