| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Sussman

Model Number : SM-RM

Certification : SGS, ISO9001, CE

Place of Origin : Wuxi Jiangsu China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 10 sets per month

Delivery Time : 60 days after deposit

Packaging Details : Standard packing

Material : 1.2-1.5MM PPGI, Steel

Forming speed : 8-12m/min

Forming stations : About 12 stations

Decoiler : 3 Tons manual one

Roller material : Gcr15 steel with quenching

Product name : hat furring channel omega profile top hat batten machine

Machine weight : 3 tons

Container : need 20 feet container

1.2 - 1.5mm Thickness Top Hat Rail Din Rail Roll Forming Machine For Electrical Box

Technical parameter

| Item | Technical data |

| Steel sheet thickness | 1.3-1.5mm galvanized steel,PPGI,GI |

| Hydraulic power | 5.5kw |

| Transmission way | chain |

| Decoiler | 3 Tons passive |

| Forming Speed | 8-12m/min |

| Roller Groups | about 12 rollers |

| Roller Material | 45# high grade steel with finish machining treatment, by high frequency quenched HRC58-62 |

| Roller Diameter | 60mm |

| Principal Axis | 45# high grade steel with quenching treatment |

| Main Motor Power | 4 KW |

| Dimension | About 4.5*0.8*1.200m |

Main Components

| Machine name | Quantity |

| 3T passive uncoiler | 1 set |

| Main roll forming system | 1 set |

| Hydraulic stop cutting system | 1 set |

| 4 meters out tables | 1 ste |

| PLC control box system | 1 set |

| Toll box | 1 package |

| Safety cover | 1 unit |

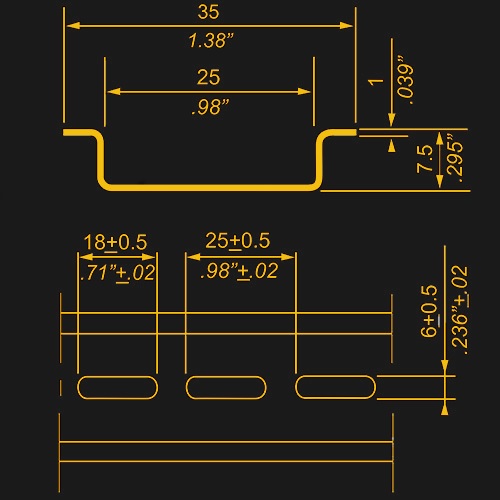

Din rail profile

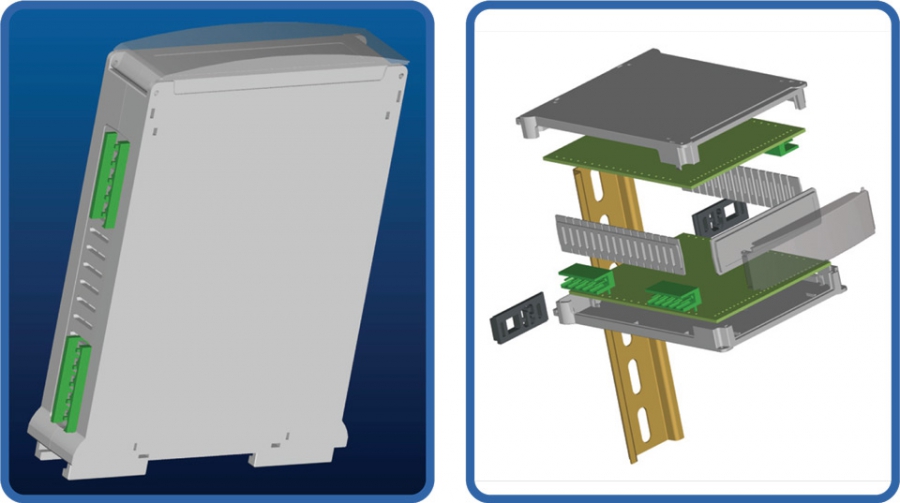

Applications

Hat Type Din Rail Machine Advantage

1.The roller is solid and electroplated, which will not have rust

2.The material are all national standard.

3.The board is cost iron frame and all milled and polished.

4. Only need one main power wire

5. Two people to operate it

6. Compacted machine to save space

|

|

1.2 - 1.5mm Thickness Top Hat Rail Din Rail Roll Forming Machine For Electrical Box Images |